Unlike airplanes or cars, high-speed trains cannot directly use energy from burning fuel; they rely entirely on electrical energy to maintain operation.

Power Supply for High-Speed Rail

What sets high-speed rail apart from other forms of transportation, such as cars or airplanes? The answer lies in the method of energy supply. While cars and airplanes can use fossil fuels directly for operation, high-speed rail depends entirely on electrical energy. To understand this better, we need to explore how the high-speed rail system obtains and utilizes electrical energy.

The power supply system for high-speed rail consists of two main components: the power source and the power supply equipment.

- The power source is where the system derives its energy, including electrical fields, generators, and batteries.

- Power supply equipment is responsible for transmitting electrical energy from the source to the locomotives of the high-speed trains through components such as cables, guiding rails, transformers, and motors.

In modern high-speed rail systems, alternating current (AC) is typically used as the primary power source. AC has higher transmission efficiency and better controllability compared to direct current (DC). The AC power is boosted by transformers and delivered to the components of the high-speed train via cables. Here, AC will be converted to DC if necessary to control the motors of the locomotives, supplying power for the train’s movement.

Most high-speed rail systems worldwide use high-voltage alternating current, such as 25kV AC. Some older systems or certain urban rail systems may use direct current.

High-speed rail uses two primary power supply methods:

Overhead lines, which is the most common method. High-voltage power lines are suspended on poles or towers along the tracks. Trains draw electricity through specialized contact components known as “contact shoes” that slide over these conductors.

The third rail, which is less common than overhead lines. A third rail is placed parallel to the two main rails. Trains draw electricity through a sliding contact with this third rail.

Internal Power Distribution System of High-Speed Trains

Not only do high-speed rail systems need energy for movement, but they also require the distribution of electrical energy to various components to ensure stable and safe operation. Inside each high-speed train, the power distribution system is responsible for supplying energy to different subsystems, including traction systems, air conditioning, lighting, and communication systems. This ensures that all operations on the train run smoothly, from speed control to maintaining a comfortable environment for passengers.

The complexity of the power supply system in high-speed trains means that careful calculations are needed to optimize energy usage. From the electrical transmission system to the subsystems within the train, everything is tightly interconnected, creating a continuous and efficient energy supply chain. However, with high speeds, the energy consumption demand significantly increases, posing a major challenge in maintaining performance without excessively raising operational costs.

With high speeds, energy consumption demand increases significantly.

Speed and Energy Consumption: An Inseparable Relationship

One of the most important factors determining the energy consumption level of high-speed trains is speed. Kinetic energy, a physical quantity directly related to “speed,” is a crucial factor in determining energy consumption. According to physical principles, kinetic energy increases with the square of speed, meaning that as speed increases, energy consumption also rises exponentially.

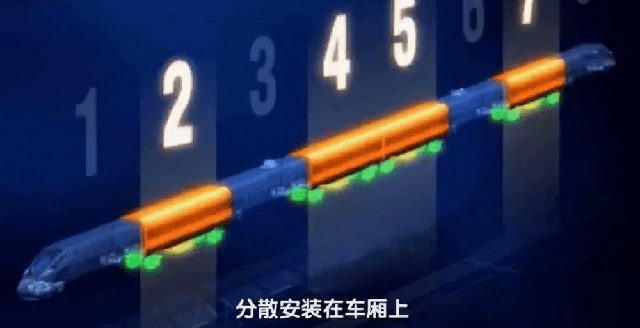

This explains why high-speed rail technology always faces the challenge of maintaining high performance while ensuring safety and controlling energy consumption levels. One solution that high-speed train designers have adopted is the use of a decentralized design model. Instead of using a single locomotive to pull the entire train like traditional trains, high-speed trains use smaller locomotives distributed within each car, allowing for more even power distribution and optimizing energy usage.

This decentralized design offers many benefits but also creates challenges. On one hand, it enhances energy efficiency as each car has its own electrical system. However, the need for each car to have its own electrical system also increases overall energy consumption since energy losses from each individual system will accumulate.

The most important factor determining the energy consumption level of high-speed trains is speed.

Operating Costs of High-Speed Rail: Significant Figures

One of the largest questions regarding high-speed rail systems is operating costs. This includes energy costs, maintenance costs, and labor costs. While high-speed rail offers many advantages in terms of time and transportation efficiency, it faces the difficult reality of very high operating costs. This is particularly true regarding energy costs, a primary factor determining the financial consumption level of the system.

As the speed of high-speed trains increases, the amount of electricity consumed also rises, meaning that electricity prices increase significantly. In addition, maintenance costs are another factor that cannot be overlooked. Operating at high speeds causes rapid wear and tear on the components of the high-speed rail system, from guiding rails to the electronic components within the trains. This necessitates frequent and thorough maintenance, further increasing operating costs.

However, from a national perspective, the value of high-speed rail systems lies not only in direct profits but also in the long-term benefits they bring to the economy. High-speed rail provides critical infrastructure, promotes regional economic development, and creates effective connections between different areas. At the same time, it offers people a convenient and fast mode of transportation, contributing to an improved quality of life.