Engineers at the Massachusetts Institute of Technology (MIT) have developed a type of speaker as thin as a sheet of paper that can turn any surface into a sound source.

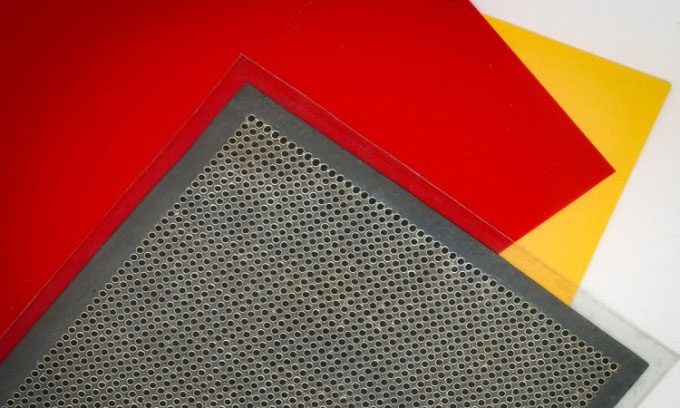

The new ultra-thin speaker produces sound with minimal distortion while using significantly less power compared to conventional speakers. The palm-sized speaker created by the research team weighs as much as a coin but can deliver high-quality sound regardless of the surface it is placed on. To achieve these advantages, the research team pioneered a manufacturing technique that requires only three basic steps and can be scaled up to produce ultra-thin speakers large enough to be installed in cars or adhered to walls.

The new ultra-thin speaker can be mass-produced. (Photo: Felice Frankel)

The new speaker model is equipped with active noise-canceling technology for noisy environments like airplane cockpits. This flexible device can also be used for entertainment by providing surround sound in theaters or amusement parks. Due to its ultra-lightweight design and minimal power requirements, the speaker is ideal for use in smart devices with limited battery capacity. Vladimir Bulović, head of the Organic and Nano-Structured Electronics Laboratory (ONE Lab) at MIT, and his colleagues announced their research findings on April 26 in the journal IEEE Transactions of Industrial Electronics.

Conventional speakers in earbuds or sound systems use an electric current passing through a coil to generate a magnetic field that vibrates the speaker diaphragm, producing the sound we hear. In contrast, the new speaker simplifies the design by using a thin film diaphragm made from piezoelectric material. This structure vibrates when an electric potential is applied, displacing the air above it and generating sound. Most film-based speakers are designed without supports because the film must bend freely to produce sound. Placing the speaker on a surface would hinder its vibrations and limit sound production.

To address this issue, the MIT research team modified the speaker design. Instead of allowing the entire material to vibrate, they relied on small domes on the thin piezoelectric material layer. Each dome, as wide as a few human hairs, can vibrate independently. Surrounding these domes are cushioning layers above and below the film to protect them from the adhesive surface while still allowing free vibration. The cushioning also protects the domes from wear and tear during daily use, enhancing the speaker’s durability.

The domes are only 15 microns high, about 1/6 the thickness of a human hair, and move up and down by 0.5 microns when vibrating. Each dome acts as an individual sound-generating unit, so thousands of tiny domes must vibrate together to produce audible sound. Because the domes vibrate instead of the entire film, the speaker has a sufficiently high resonant frequency to be effectively used in ultrasound imaging. This imaging method uses very high-frequency sound waves to produce images. The higher the frequency, the better the resolution of the captured images.