Scientists have added a special powder to 3D printing resin so that it can be easily repaired on-site when broken.

Professor Cyrille Boyer, along with experts Nathaniel Corrigan and Michael Zhang from the School of Chemical Engineering at the University of New South Wales (UNSW), have discovered a new method that allows 3D printing resin to self-heal at room temperature using only light, as reported by Phys on December 18. The research results were published in the journal Angewandte Chemie International Edition.

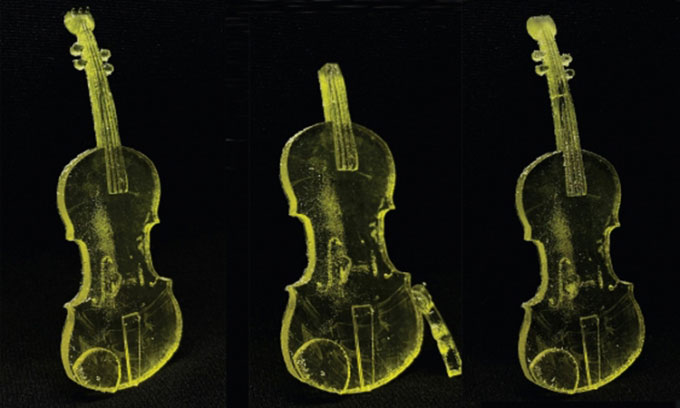

3D printed violin with self-healing additives under ultraviolet LED light. (Photo: UNSW)

The research team added a special powder to the liquid resin used in the printing process, facilitating repairs when the material is broken. This can be easily accomplished by shining standard LED light onto the 3D printing resin for about an hour, triggering a chemical reaction that unites the broken pieces. The entire process even makes the repaired resin stronger than it was originally.

The researchers hope that the development and commercialization of this new technique will reduce chemical waste, as broken plastic pieces do not need to be discarded or recycled, and can be simply repaired even when embedded in a component made of multiple materials. This new technology has potential applications in wearable electronics, sensors, and even in the production of shoes.

“You can apply this technology in many places, for example, those using polymer materials. If a part breaks, you can repair it without discarding it. The environmental benefits are clear because you do not need to synthesize a completely new material every time it breaks. We are extending their lifespan, helping to reduce plastic waste,” Corrigan stated.

The powdered additive used by the team is trithiocarbonate, developed by the Commonwealth Scientific and Industrial Research Organisation (CSIRO) in Australia. It allows for the rearrangement of the nanoscale network of the elements that make up a material and unites the broken pieces. This occurs within 30 minutes when ultraviolet LED light is directly applied to the broken area. The resin will fully heal after about an hour. Tests, including those on the 3D printed violin, show that the resin after healing is very strong.

Based on the simplicity and speed of the new process compared to current 3D printing material repair methods, the research team believes that commercialization is entirely feasible.

“There are other processes that rely on thermal chemistry to repair materials, which often take about 24 hours and many heating cycles to achieve the same results. Another limitation is that they require a furnace heated to high temperatures and cannot repair plastic materials on-site. Staff must first disassemble it from the device, which adds complexity and delays,” Corrigan explained.

“With our system, you can leave the broken plastic in place and shine light over the entire device. Only the additives on the surface of the material are affected, making the repair process easier and faster,” he added.