Each time it is believed that Moore’s Law has reached its limits, scientists strive to find a new solution to extend its life once again. Now, efforts in materials science research are looking to elevate the limits of Moore’s Law to new heights.

In a recent publication in the journal Nature, scientists from Tsinghua University in Shanghai reported that they have created a gate electrode on a graphene transistor with a width of just 0.34 nanometers – equivalent to the width of a carbon atom.

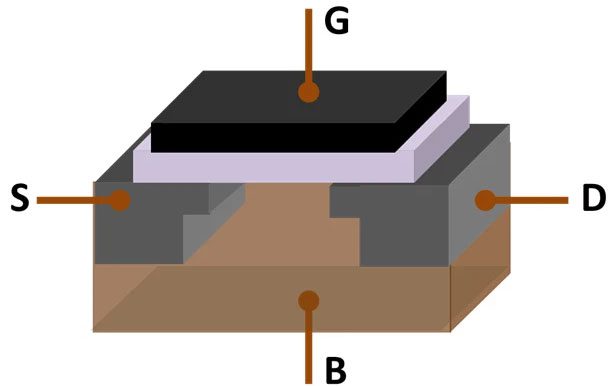

For transistors, this gate electrode is a crucial component as it is used to control the flow of electricity between the source and drain terminals. The length of this gate electrode – or the distance between the source and drain terminals – has even been named for the chip manufacturing process, serving as a parameter that indicates how advanced and high-end the chip is.

Basic components of a transistor: Gate (G), Source (S), and Drain (D)

However, from recent processes (14nm and below), these figures have become more of a marketing term and identifier as the process name no longer represents the actual length of the gate electrode. This is because if the size is reduced to match its process name, the limitations of material technology will damage the chip.

In reality, many studies have narrowed this gap down to 1nm and even lower. But this is the first time this distance has been reduced to 0.34nm – equal to the size of a carbon atom – and this may be its ultimate boundary. Research author Tian-Ling Ren stated: “This could be the final node of Moore’s Law.”

Graphene Transistors

While silicon is a suitable compound for chip manufacturing, when the gate length is reduced to below 5nm, electrons tend to leak through other terminals on the transistor. However, in 2016, using carbon nanotubes with a 2D material called Molybdenum Disulfide, researchers created a gate electrode with a length of 1nm. Despite having higher resistance than silicon, this advancement allowed Molybdenum Disulfide to push the gate length of transistors to a new limit.

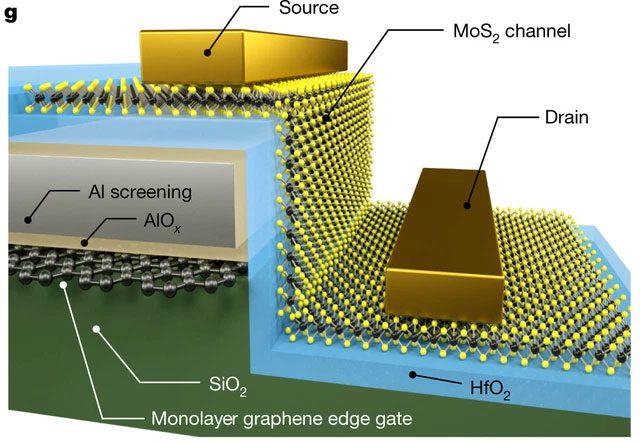

Building on this research, scientists at Tsinghua University in China also chose Molybdenum Disulfide as the material for the channel and gate electrode in their transistor. But instead of using carbon nanotubes, the researchers opted for a graphene sheet with a thickness of just 1nm.

Through a manufacturing method called chemical vapor deposition, the scientists were able to sandwich a layer of graphene between two insulating layers of aluminum oxide and silicon dioxide. The material was then etched to create a staircase shape, exposing the edge of the graphene layer in the vertical wall of the staircase. This exposed section forms the thin gate electrode that is only the size of a carbon atom.

Finally, the research team added a layer of Hafnium Oxide to create a small space between the gate electrode and the channel made from a layer of Molybdenum Disulfide. They then added two metal electrodes, above and below the material layer, to form the source and drain terminals for the new transistor.

Challenges for the Near Future

Despite achieving an almost unimaginable distance in the semiconductor world – 0.34nm – this work is merely a proof-of-concept: evidence of the researchers’ hypothesis.

This approach is suitable for producing only a very small number of transistors in a laboratory setting and is unlikely to be scalable for mass production to create chips for your smartphones or laptops. Moreover, this approach primarily uses expensive materials for production, making scaling up a challenging hurdle to overcome.

Currently, even without narrowing the gate distance on transistors, silicon chip manufacturing technology continues to make new strides in performance and energy efficiency. While FinFET-designed transistors are approaching their ultimate limits, new technologies such as chips with Gate-All-Around (GAA) designs promise to maintain the momentum of performance and efficiency gains in Moore’s Law. More importantly, these technological advancements are within reach, with new products expected to emerge in the coming years.