Rapidly Changing the Shape of Alloys in a Reversible Manner: Chemists Have Made a Significant Step Forward in Developing Reconfigurable Technology.

When fans of science fiction see the term “liquid metal”, they might think of the nearly indestructible T-1000 robot from the legendary blockbuster “Terminator” – made of “liquid metal” that can change shape at will.

Liquid Metal is 1.5 times harder than steel and also lighter.

Liquid Metal is a durable compound, 2.5 times stronger than titanium alloys while being lighter. It is 1.5 times harder than steel and also weighs less. It is difficult to permanently deform, being 2-3 times more resistant compared to traditional metals. It is completely corrosion-resistant, allowing for thinner yet sturdier shells…

A research team at North Carolina State University has taken a significant first step toward creating such alloys.

By applying a low voltage to a conductive liquid (in this case, a water solution) and adjusting its strength, the researchers were able to change the shape of gallium-indium alloy droplets in water almost instantly, causing them to either spread into long strips or contract into spheres.

Lead researcher Michael Dickey explained: “By making the metal flow and change shape, we can create transformable structures.”

The primary application chemists envision is the creation of small, adjustable metal antennas: the same type of material can be deformed to send and receive signals.

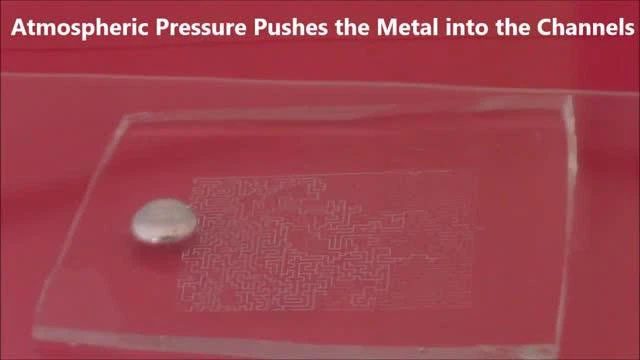

Similarly, this material could be used to create circuits that can naturally change the layout of wiring systems, much like a nervous system can create or eliminate certain connections to maintain an optimal state.

This material can be used to create circuits that can change the layout of wiring systems.

Benoit Grosdidier, an expert in liquid metals at the University of Lorraine in France, believes that the solder currently used in the microelectronics industry will be replaced by such alloys.

Benoit Grosdidier explained: “The key to the soldering process is the spreading of the solder metal and the ‘wetting of the substrate’; thus, liquid metals could replace the toxic metals currently in use (like lead) or other metals that are in short supply.”

For example, tin, which is often used for soldering due to its excellent ductility, is facing depletion of available reserves; the formula for changing ductility by applying a voltage promises to replace it with more abundant metals.

Michael Dickey acknowledged: “We are still in the early stages of research. However, he emphasized the significant advantages of liquid alloys: unlike mercury, they are non-toxic and can change shape at will.”

Everything occurs at the microscopic level, stemming from forces that ensure the droplets of liquid metal remain cohesive when they come into contact with air or liquid – this determines the final shape of the liquid metal. This force is surface tension, which can be observed on the surface of a pond where a water strider (commonly known as a water spider) walks on the surface without breaking the liquid’s surface. It is the surface tension of water that can support the weight of the water strider.

The surface tension of gallium-indium alloy is seven times that of water. In contrast to water, which disperses and flows over some surfaces, gallium-indium alloy droplets maintain a spherical shape on most surfaces to minimize their surface area contact with the outside world.

However, when these droplets are in a conductive solution connected to a power source, the metal atoms on their surfaces react with the charge in the solution to form an oxide layer. This oxide layer can reduce the surface tension of the gallium-indium alloy droplet and affect its shape, allowing the shape of the alloy to be altered by changing the voltage applied to the conductive solution.

Oxide acts as an intermediary between the metal and water in the conductive solution.

The researchers found that the oxide acts as an intermediary between the metal and water in the conductive solution. Michael Dickey explained: “The oxides contain gallium atoms, which have an affinity for the liquid metal; on the other hand, they have molecules similar to water molecules (hydroxyl groups), so they are also hydrophilic.” A voltage of less than 1 volt can be sufficient to create an oxide layer on the surface of the liquid metal that reduces the surface tension to nearly zero, causing the metal droplets to lose their spherical shape and become “a puddle.” Moreover, the researchers can also direct the liquid alloy to flow in a specific direction, and this change is entirely reversible: as soon as the power is turned off, the oxide layer disappears, and the alloy returns to its original shape, reverting to dense spherical droplets within a second.

The liquid alloy can flow along the path established by the researchers and then immediately spread out to form different shapes as if it were alive, resembling a miniaturized T-1000 robot at a more “liquid” level.