A new “nano-structured” material based on carbon promises to be a better alternative to steel, aluminum, and synthetic Kevlar fibers.

Engineers from the Massachusetts Institute of Technology (MIT), California Institute of Technology (Caltech), and the Swiss Federal Institute of Technology Zurich (ETH Zurich) have developed a new ultra-lightweight material made from nanometer-sized carbon structures resembling “stiffeners”, which offer greater mechanical strength and elasticity.

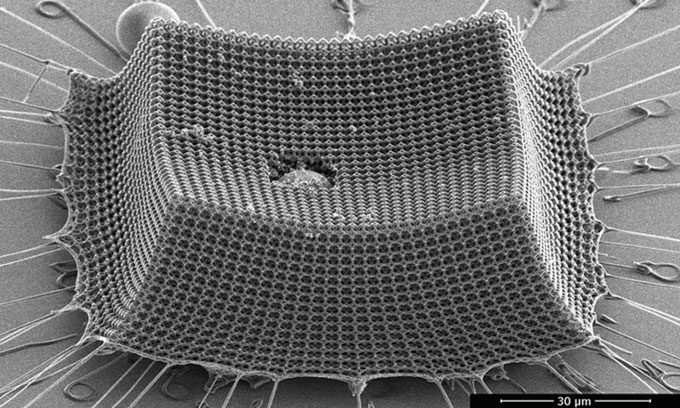

Crystal network configuration of the new nano material. (Photo: MIT).

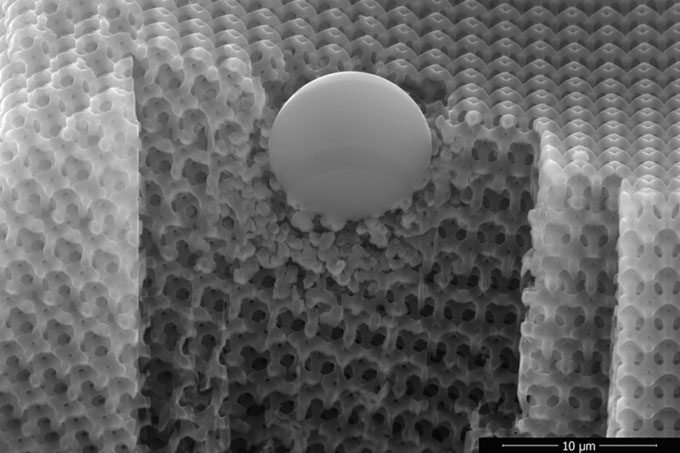

The research team tested the material’s elasticity by firing silicon dioxide microparticles (with a diameter of just 14 micrometers) at supersonic speeds and found that, with a thickness thinner than a human hair, the material could effectively stop projectiles from penetrating it.

Calculations indicate that compared to steel, aluminum, Kevlar, and other impact-resistant materials of similar mass, the new material has a significantly higher impact energy absorption capability. If produced on a large scale, it could very well become an affordable alternative.

“The knowledge gained from this research can provide design principles for ultra-lightweight impact-resistant materials for use in armor, protective coatings, and blast shields in the defense and aerospace sectors,” said Julia R. Geer, a professor of materials science, mechanics, and medical engineering at Caltech and co-author of the study.

Depending on how they are arranged, nano-structures can impart unique properties to materials, such as lightness and exceptional resilience. The research team began exploring this type of material under rapidly deforming conditions, such as high-speed impacts.

Microscale silicon dioxide projectile unable to penetrate the thinner-than-hair membrane from the new material. (Photo: MIT).

At Caltech, they first created a nano-structured material using two-photon lithography technology—a technique that employs high-powered, fast lasers to solidify nano-structures in a type of photoresist. The team successfully constructed a repeating crystal network configuration known as a tetrahedral structure, comprising extremely small stiffeners.

“While carbon is inherently brittle, the arrangement and small size of the stiffeners in the new nano-structured material create a bendable architecture similar to rubber,” emphasized Carlos Portela, an associate professor of mechanical engineering at MIT and the lead author of the study.

After shaping the crystal network structure, the researchers washed away the residual resin and placed it in a high-temperature vacuum oven to convert the polymer into carbon, ultimately resulting in a super-strong, lightweight carbon material.

In the future, Portela plans to further explore different nano-structural configurations, as well as materials beyond carbon, and to find ways to scale their production. Details of the research were published in the journal Nature Materials on June 24.