Instead of relying on fossil fuel extraction, the prevalent type of fuel for jet engines can now be produced completely clean and without any emissions.

The dream of a system that can turn ordinary air into fuel is no longer science fiction. Aldo Steinfeld, a professor at the Department of Mechanical and Process Engineering at ETH Zurich, stated that he has developed a solar-powered filtering system capable of converting ordinary air into jet fuel kerosene.

In a two-year feasibility demonstration conducted on the roof of the ETH Zurich Machine Laboratory, Prof. Steinfeld’s small-scale solar filtering system showcased how it operates, paving the way for potential scalability of the project.

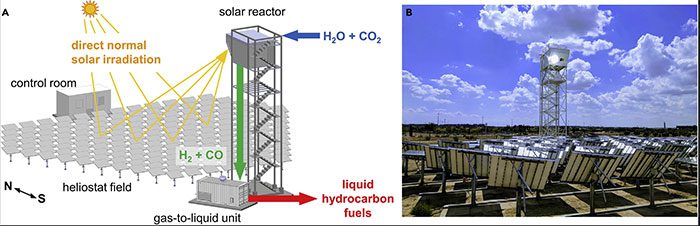

Model of the solar-powered jet fuel production system by Prof. Steinfeld.

Utilizing solar energy, this system extracts CO2 and water from the air and then separates them to synthesize a gas mixture, which includes hydrogen and carbon monoxide. This gas mixture is then processed into kerosene to be used as jet fuel.

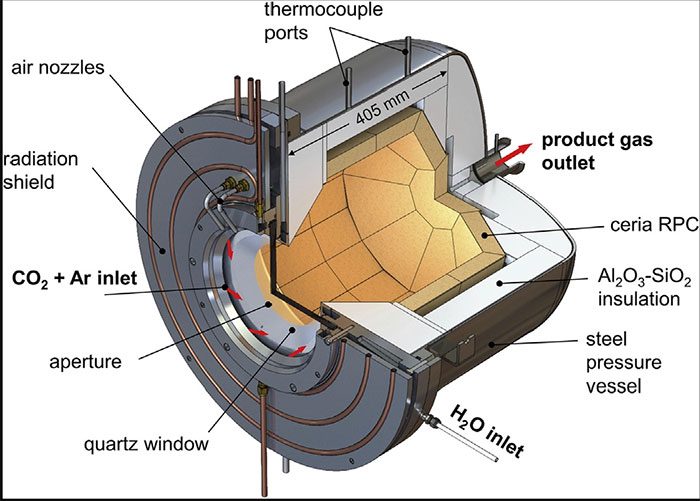

According to Prof. Steinfeld, “the biggest challenge is designing the solar reactor. We have to evaluate the reactor’s performance based on five key indicators and assess its stability during operation, as well as fully integrate it into the fuel production tower.”

Diagram of the solar reactor for separating CO2 and water through a thermal redox cycle using CeO2.

From a small-scale experiment, this project has now evolved into a larger scale. The goal is to determine the economic efficiency of this technology as the conversion efficiency of solar energy into kerosene increases.

To help bring this research project to fruition, Synhelion, a spin-off company from the Myas Laboratory at ETH Zurich, plans to operate a solar fuel tower on an industrial scale in Jülich, Germany. Last March, Swiss International Air Lines announced that they would be the first airline to use this solar-produced kerosene for their aircraft.

The success of this experiment marks a significant milestone for scaling up the project. Steinfeld stated that an industrial-scale solar-powered fuel production plant could harvest 100 MW of solar energy to produce about 9 million gallons (nearly 41 million liters) of fuel annually.

The production of this type of fuel undergoes three transformation stages in a continuous chain. First, the tower draws in surrounding air to extract CO2 and water before using the oxidizing agent CeO2, combined with solar radiation to heat the chemicals, transforming CO2 and water into a gas mixture of hydrogen and CO. The third stage involves liquefying this synthetic gas, converting it into liquid hydrocarbons that can be used as kerosene for jet fuel.

Solar fuel production tower operational in Jülich, Germany

Notably, this process is completely carbon neutral, as it uses solar energy for production and only emits an amount of CO2 equivalent to what is extracted during production. Even if all the materials used to construct the tower are produced using renewable energy, the entire process will have zero emissions.

While most studies on reducing carbon emissions typically focus on electric vehicles, they often overlook the aviation industry – a significant contributor to current air pollution. This is why Prof. Steinfeld has placed such emphasis on this project.

“This emission can be avoided by replacing current fossil fuels with solar-produced aviation fuel,” Prof. Steinfeld stated. “It is important to note that this kerosene is fully compatible with existing infrastructure for fuel storage, distribution, and powering jet engines, and it can also be blended with fossil-derived kerosene. Thus, this solar-produced kerosene can help make the aviation industry more sustainable.”