The ultra-thin and lightweight solar fabric developed by the Massachusetts Institute of Technology has a power output per kilogram that is about 18 times higher than traditional solar panels.

A team of engineers at the Massachusetts Institute of Technology (MIT) has developed an ultra-light solar fabric that weighs only 1/100th of a traditional solar panel. This innovative fabric is made from semiconductor ink and utilizes scalable printing processes for future mass production. The research was recently published in the journal Small Methods on December 9.

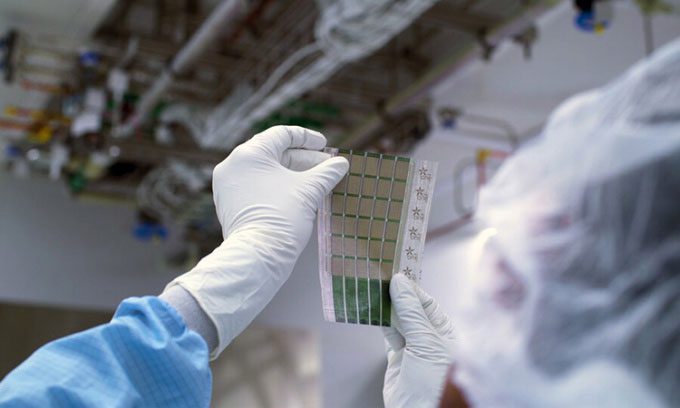

The MIT research team has developed ultra-thin, lightweight solar panels that can be adhered to nearly any surface. (Photo: Melanie Gonick/MIT)

The new solar panels are flexible, durable, and significantly thinner than a human hair. They can provide power while users are on the move, taking the form of wearable energy fabric, or be transported to remote locations and deployed quickly in emergency situations. Due to their lightweight and thin nature, the new solar panels can be applied to various surfaces, such as the sails of a ship, tarps used in disaster recovery, or the wings of drones.

To manufacture the solar panels, the team used nanomaterials in the form of printable electronic ink. They then sought a lightweight, flexible, and robust substrate to attach these hair-thin panels, making them easy to install and more tear-resistant. Ultimately, they identified the ideal material as Dyneema, a synthetic fabric weighing just 13 grams per square meter.

During testing, the MIT research team found that the solar fabric could generate 730 watts of electricity per kilogram when standing alone, and about 370 watts per kilogram when deployed on the ultra-durable Dyneema fabric. This means the power output per kilogram is approximately 18 times higher than traditional solar panels.

“A typical rooftop solar system in Massachusetts has a power output of around 8,000 watts. To generate the same amount of electricity, our solar fabric would only add about 20 kg to the roof,” said Mayuran Saravanapavanantham, co-author of the study and a graduate student in electrical engineering and computer science at MIT.

The experts also tested the durability of the solar panels and found that, after rolling and unrolling the fabric panels over 500 times, they retained over 90% of their initial power generation capacity.

Despite being much lighter and more flexible than traditional panels, the new solar fabric needs to be encased in another material to protect it from environmental factors. Additionally, the organic carbon-based materials used to produce the panels can degrade when exposed to moisture and oxygen in the air, reducing performance.

“Encasing the solar fabric in heavy glass, similar to traditional silicon solar panels, would negate the value of this advancement. Therefore, we are developing ultra-thin packaging solutions that only slightly increase the weight of the current ultra-light devices,” said Jeremiah Mwaura, a scientist at MIT’s Electronics Research Laboratory.