Scientists from BAE Systems, a defense and aerospace company, have invented a super-adhesive polymer called Synthetic Gecko, which mimics the feet of geckos.

|

|

(Photo: BBC) |

The inventors of this adhesive state that just one square meter of this material can hold a weight equivalent to that of a medium-sized family car.

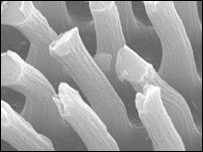

Similar to the feet of reptiles, this new polymer is covered in millions of tiny mushroom-like fibers that enhance its adhesive capabilities.

In the future, this polymer could be used in aircraft repair materials, patching fabrics, or even for sewing costumes similar to those worn by Spider-Man.

Dr. Sajad Haq, a researcher at BAE Systems’ High Technology Center, stated: “With this adhesive, window cleaners could ditch their ladders and climb straight up walls. The number of other applications for this adhesive may only depend on human imagination.”

Synthetic Gecko is not the first material inspired by cold-blooded creatures. In 2003, a research group from the University of Manchester developed a type of tape also based on the structure of a chameleon’s foot.

|

| Synthetic Gecko is composed of millions of mushroom-like fibers (Photo: BBC) |

This invention is based on research by American scientists about the remarkable climbing abilities of geckos. A team from the University of California discovered that the gecko’s adhesive ability comes from weak molecular forces generated by billions of tiny structures, known as setae, on each gecko foot.

These forces, known as van der Waals forces, occur between molecules with different electric charges, causing them to attract each other. The accumulated attraction from billions of setae allows geckos to run along walls and even hang upside down on flat glass surfaces. This adhesion is only released when the gecko separates its foot from the surface.

BAE’s research team has created a material that mimics the setae of geckos. This adhesive is made from a polyamide, similar to nylon, and is coated with millions of tiny mushroom-like fibers.

Although this material has excellent adhesive properties, it does not feel “sticky” to the touch. Dr. Haq explained: “It only sticks when you press this material against a surface. The molecular interaction is what gives it its adhesive capability.”

|

|

The new material can stick to almost any surface (Photo: BBC) |

This material is manufactured using an improved version of a photolithography technique, commonly used to create silicon chips. This technique employs light to engrave three-dimensional patterns into a material.

Dr. Haq noted: “The processes we use are standard electronic manufacturing processes that have been enhanced. They are inexpensive, easy to use, and can easily produce large sheets of adhesive at a low cost.”

Previous attempts to create “gecko materials” often involved complex techniques like electron beam lithography, which are expensive and difficult to scale for mass production.

So far, the research team has developed several different types of materials with varying sizes of “mushroom-like fibers” to optimize its adhesive capabilities. They have created samples with diameters of up to about 100mm that can adhere to almost all types of surfaces, including dirty ones.

However, the research team has yet to achieve the same level of adhesion as that of real geckos. Dr. Haq remarked: “The material we have developed can hold a car on a ceiling, or even an elephant if we wanted. However, we have not yet truly achieved the adhesive capability of geckos.”