The mask worn by the South Korean forward was created using 3D printing technology, a solution increasingly applied in modern medicine.

Son Heung-min had to wear a mask while competing in the 2022 World Cup as a protective measure after sustaining an injury. This player’s mask is designed to protect the facial bones from impact, reducing the risk of further serious injury.

The forward of the South Korean national team is not the first athlete to use this device for enhanced protection, allowing them to continue competing during the recovery phase from an injury. Sports masks have become a prominent application of 3D printing technology in medicine.

Son Heung-min wearing a 3D-printed mask made from carbon fiber. (Photo: The Athletic).

Solutions in the Mask

For athletes, injuries are difficult to avoid, especially in high-contact sports such as boxing, basketball, rugby, and soccer. Some injuries can occur in the facial area. Protective masks are a supportive solution for injuries such as nasal fractures and cheekbone fractures.

There are mass-produced sports masks available in standard sizes like clothing and footwear. However, professional athletes often seek personalized solutions.

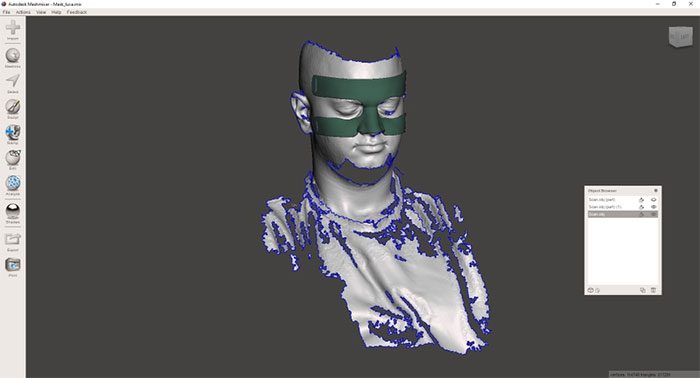

Specialized equipment used for 3D scanning a person’s face. (Photo: Creamed).

For example, in 2017, YoungNext created a mask specifically for Sergio Ramos when the defender sustained a facial injury. In the first step, they used a scanner to capture a 3D image of the face. This solution is more efficient and time-saving compared to traditional plaster casting methods.

Today, there are many advanced scanners that support facial recognition and hair separation to produce an accurate 3D model of the individual’s face.

In the next step, designers use CAD (Computer-aided design) software to shape the mask. The designer must have a clear understanding of the injured area and how to incorporate protective framing.

“Certain design changes must be made, such as holes for straps, areas for material contact with the face, injury areas, and stress-absorbing sections. Additionally, providing a wide field of vision is crucial for athletes to ensure their sight is not obstructed,” Creamed stated.

The mask is designed to fit snugly on the wearer’s face. (Photo: Creamed).

Once the design is completed, it is sent to the 3D printing department. Traditional production methods use rigid plastics, materials like polycarbonate to print the protective mask. In contrast, elite players like Son Heung-min wear masks made from carbon fiber, which are stronger and lighter. Additionally, the interior of the product has EVA padding to increase comfort while wearing.

There is no exact pricing framework for the entire manufacturing process. In Ramos’s case, YoungNext charged the PSG defender 300 euros for the carbon mask.

A Billion-Dollar Industry

According to a report from Precedence Research, the 3D printing market for medical applications was estimated to be worth $1.45 billion in 2021. The market size is expected to reach $6.21 billion by 2030, growing at a rate of 17% per year.

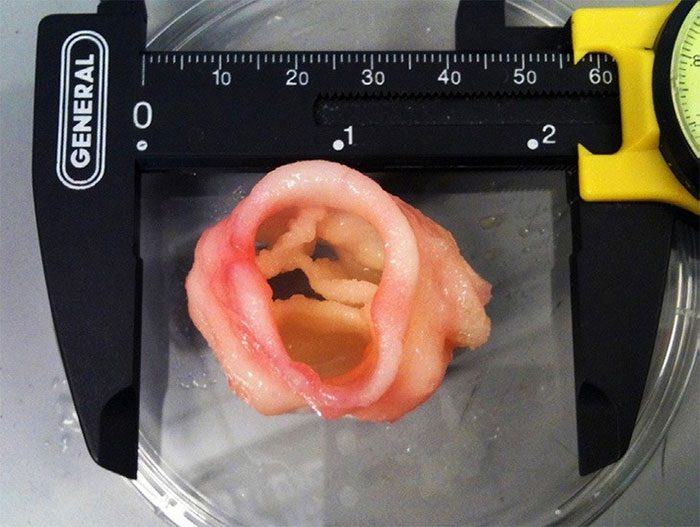

Heart valve printed using bioprinting technology. (Photo: 3dprintingindustry).

Among these applications, 3D printing sports masks to assist athletes in recovery is a small segment of this technology. In the medical field, 3D printing is applied in joint replacements and the grafting of artificial bones using specialized replacement materials.

Creating prosthetic limbs that match the size and are personalized for each patient’s injuries is also an application of this technology. Prosthetic limbs made from composite plastics or carbon fiber have many advantages over traditional materials.

The next advancement of this solution is the printing of human organs and parts, combined with stem cell technology.